Chocolate moulds and vibration-induced stress – Schokoladenformen und Belastungen durch Vibrationen

The ‘INFORM’ research project, which we initiated, has been running since 2018. This investigates the damage caused to moulds as a result of vibration. This research project is supported by the Central Innovation Programme for SMEs (ZIM), which is in turn a project of the Federal Ministry for Economic Affairs and Energy (BMWi).

In partnership with the University of Stuttgart’s Institut für Kunststofftechnik (IKT, Institute for Plastics Technology), the first phase of this project analysed the physical correlations and stresses that come into play when chocolate moulds are subjected to vibration.

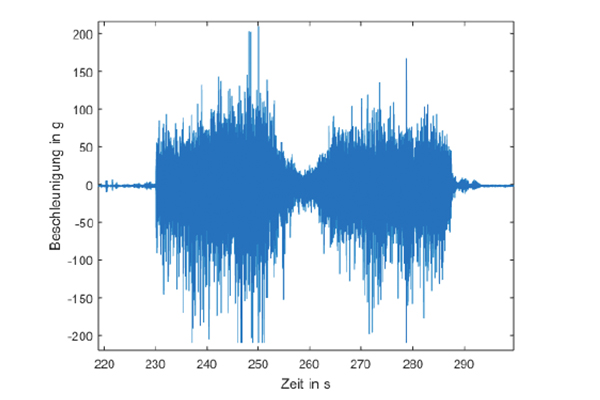

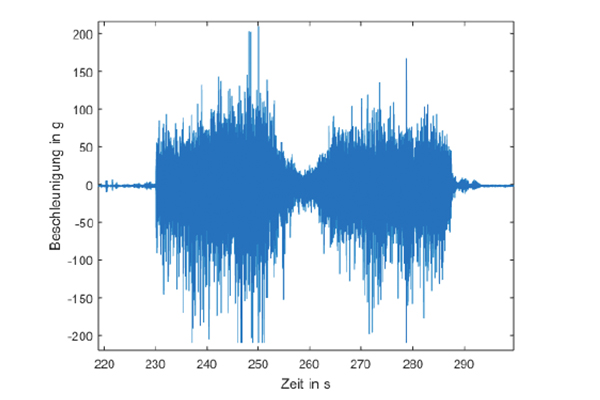

The interim findings will first be published in the December 2020 edition of the Hansa-Verlag magazine ‘Kunststoffe’ (‘Plastics’). One surprising finding was the high level of vibration-induced stress that chocolate moulds are exposed to as they pass along vibration lines. This vibration, which takes place immediately after dispensing, is required to distribute the chocolate evenly in the cavities.

Measured accelerations of up to 200 times the force of gravity result in high oscillation amplitudes. If circumstances are unfavourable, this can quickly push chocolate moulds to their limits.

In these rare cases, fissures can form around the supports on the rear. If these spread, this can lead to forced rupture. Although they are rare, it was these occurrences that motivated us to initiate the ‘INFORM’ project.

Measured acceleration values

The project will then go on to outline recommendations for action to enable chocolate manufacturers to reduce stress on the moulds.

A further intention is to develop concrete technical solutions for the design of chocolate moulds to reduce the effects of vibration on the moulds and increase their service life. Mould geometry and material selection offer some starting points for this.

We will include further details from this first part of the project in the next newsletter. We will also systematically present the various causes of chocolate mould breakage to make it easier to select targeted measures to increase the service life of chocolate moulds.

Seit 2018 läuft das von uns initiierte Forschungsprojekt „INFORM“ zum Thema Formenschäden im Zusammenhang mit Vibrationen. Dieses Forschungsprojekt wird im Rahmen des Zentralen Innovationsprogramms Mittelstand (ZIM) des Bundesministeriums für Wirtschaft und Technologie (BMWi) gefördert.

In Zusammenarbeit mit dem Institut für Kunststoff (IKT) der Universität Stuttgart wurden in der ersten Phase die physikalischen Zusammenhänge und Belastungen analysiert, die durch Vibrationen auf Schokoladenformen wirken. In der Dezemberausgabe 2020 der Zeitschrift „Kunststoffe“ des Hansa- Verlags erscheint eine erste Veröffentlichung der Zwischenergebnisse.

Überraschend sind die hohen Beanspruchungen, denen Schokoladenformen durch Vibrationen in Rüttelstrecken ausgesetzt sind. Dieses Vibrieren unmittelbar nach der Dosierung ist nötig, um die Schokolade in den Kavitäten zu verteilen.

Gemessene Beschleunigungen von bis zum 200fachen der Erdbeschleunigung bewirken hohe Schwingungsamplituden. Diese können unter ungünstigen Umständen Schokoladenformen schnell an ihre Grenzen bringen.

In diesen seltenen Fällen können sich Risse im Bereich der Stege an den Rückseiten bilden, was durch fortschreitende Rissausbreitung zum Gewaltbruch führen könnte.

Diese seltenen Vorkommnisse haben uns dazu motiviert, das Projekt „INFORM“ zu initiieren.

Gemessene Beschleunigungswerte

Im weiteren Verlauf dieses Projektes sollen Handlungsempfehlungen für die Schokoladenhersteller beschrieben werden, wie die Belastung der Formen verringert werden kann.

Darüber hinaus sollen aber auch konkrete technische Lösungen für die Auslegung von Schokoladeformen entwickelt werden, um die Folgen von Vibrationen für die Formen abzumildern und die Lebensdauer der Formen zu erhöhen. Ansatzpunkte dazu bietet die Formengeometrie und Materialauswahl.

Im nächsten Newsletter werden wir weitere Details des ersten Projektteils zeigen. Darüber hinaus werden wir die verschiedenen Bruchursachen von Schokoladenformen systematisch darstellen, um die Auswahl zielgerichteter Maßnahmen zur Lebensdauerverlängerung von Schokoladenformen zu erleichtern.