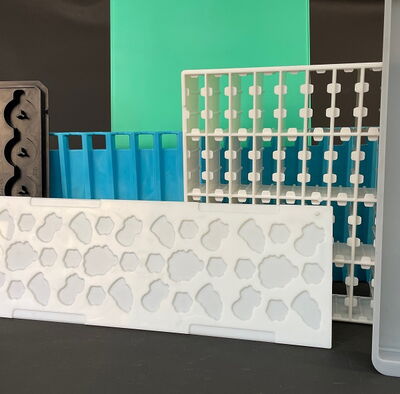

Customised handling solutions

Solutions for the chocolate industry

Brunner's range of solutions is not limited to chocolate moulds.

In cooperation with our customers and their suppliers for process automation, we develop individual solutions for

- Biscuit or wafer feeders/buffer storage containers

- Packaging blister holders

- Different types of demoulding/storage plates

- Customised containers for internal transportation/storage

These parts are usually developed within a project for the production of new items or automation.

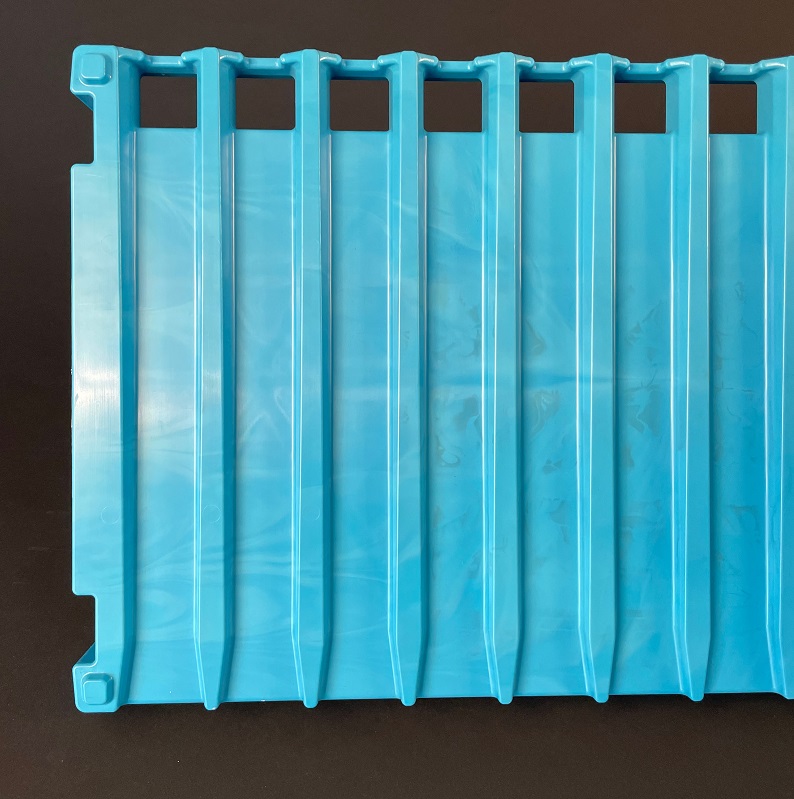

Biscuit and wafer feeder

Wafers or biscuits can be stored and transported from the place they were manufactured to the feeding spot where they "meet" the chocolate.

Thanks to exact geometrical fixation, they can be accurately positioned where they need to fit.

(Wafer feeder)

(Wafer buffer)

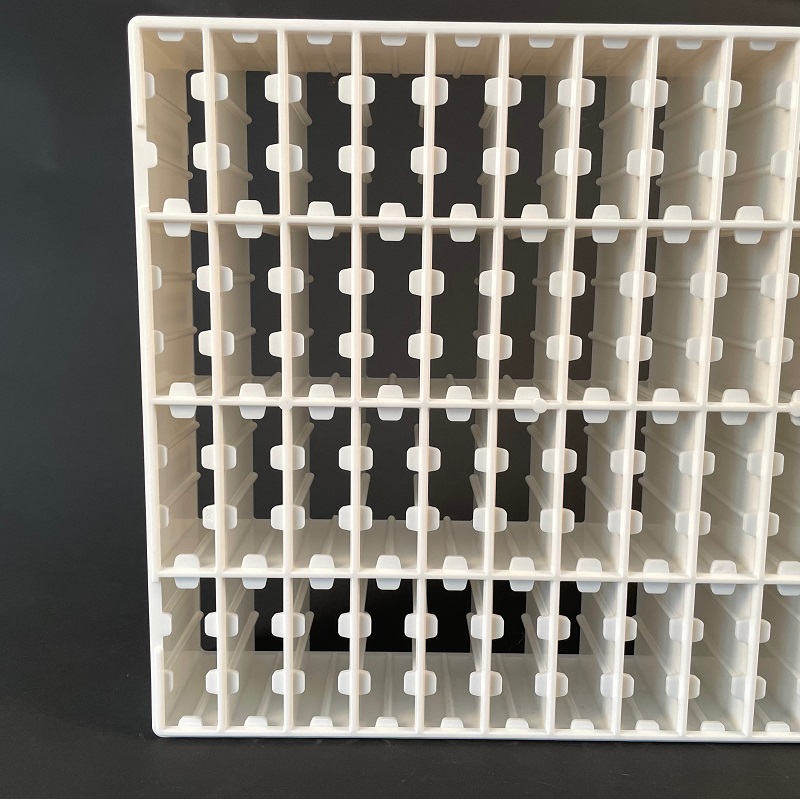

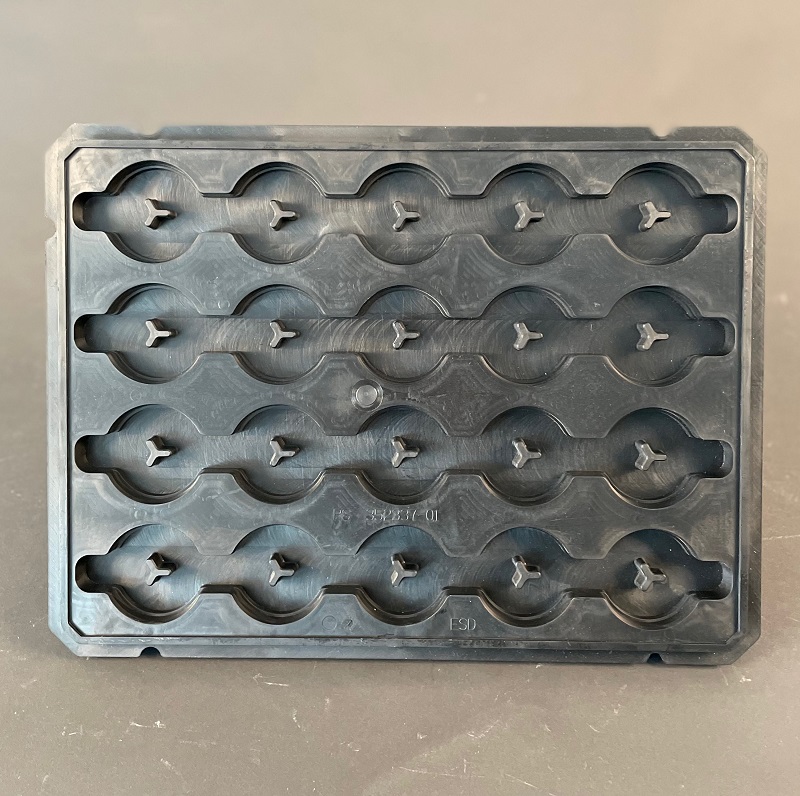

Packaging blister holders

Blister holders are used in a second circuit near the chocolate moulding circuit. Packaging blisters are singularised and placed into these holders. The holder with the blister is brought into a position suitable for a robot with vacuum suckers to place the de-moulded chocolates into the packaging blisters.

(Blister holder)

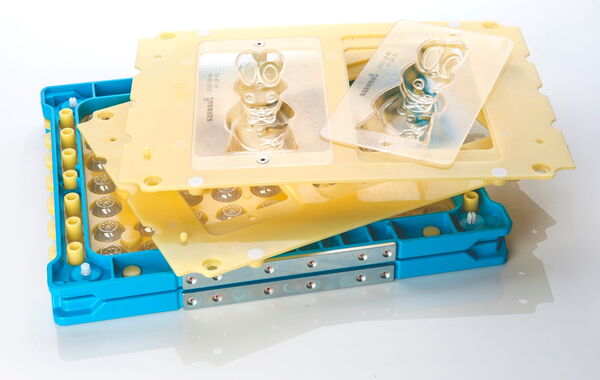

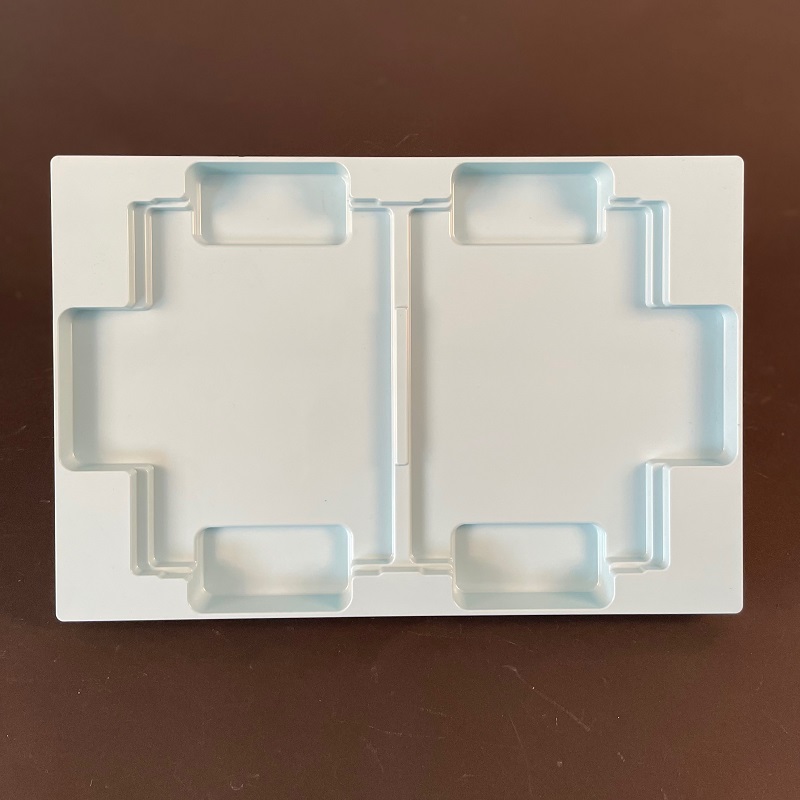

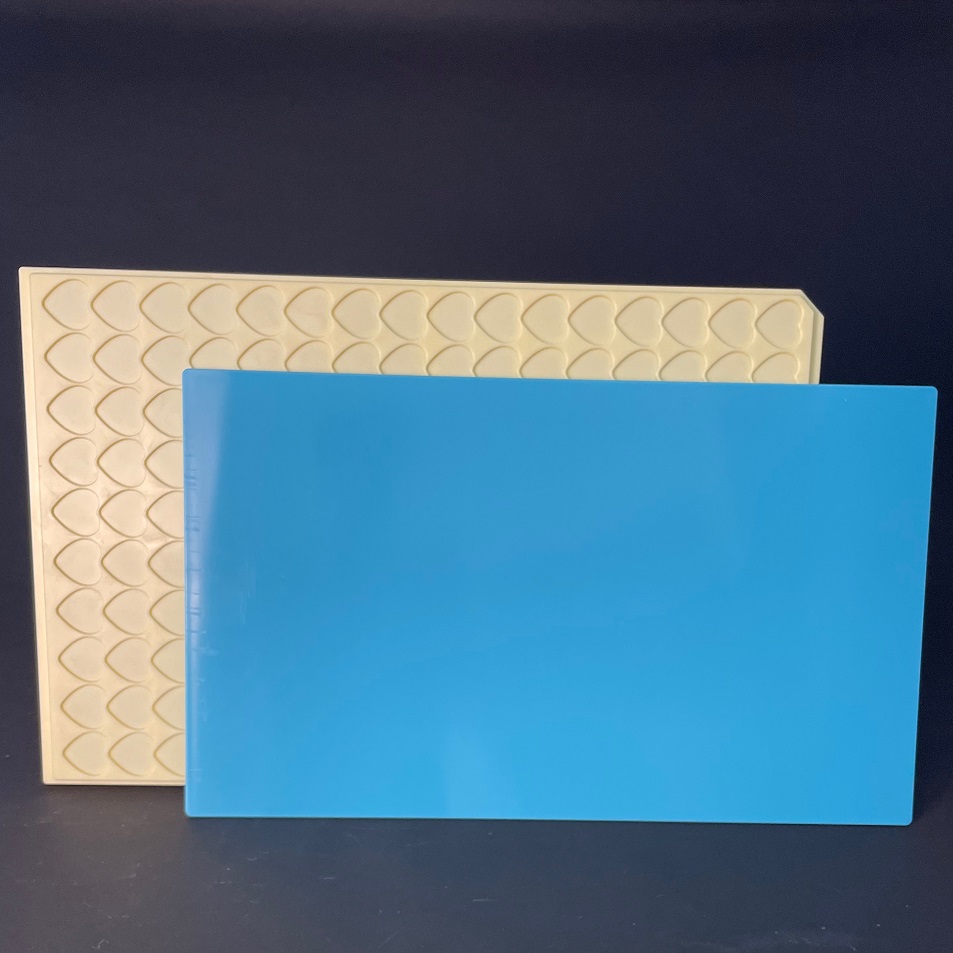

Demoulding plates

Chocolates are deposited in a regular pattern on demoulding plates. These are used in case the chocolates needs to be brought into a buffer storage for technical reasons (failure in the packaging line) or if they need to be put into interim storage before they are assembled to assortments of chocolates or pralines.

The surfaces of the plates can be plain or they can have pre-shaped footprints of the chocolates.

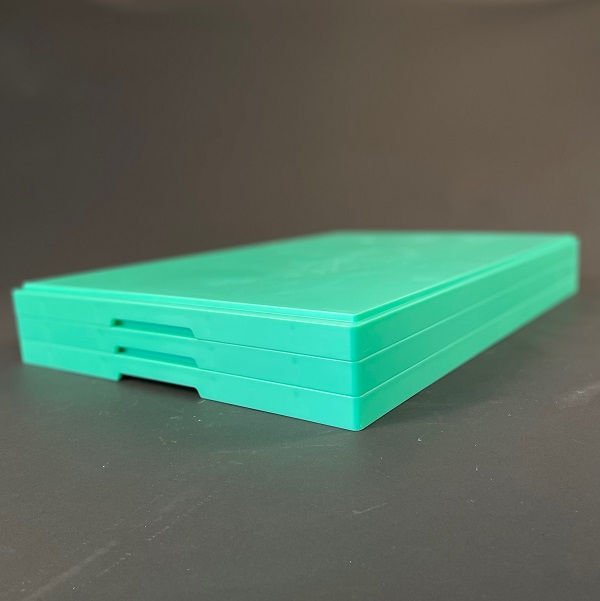

On the one side, there are demoulding plates that are simply flat. With these simple versions, there are systems in which the chocolates themselves work as spacers when stacked. In other logistic applications, they are pushed into rails on a rack to create a distance between the chocolate and the next plate above.

Other versions are stackable and can be centered to avoid that chocolates get in touch with the lower side of the upper plate.

(Demoulding plates with and without contour)

(Stacked demoulding plates)

Individual containers for production logistics

The containers can be individually adapted to any rack or transport system. The different variants include plain or structured surfaces, with a frame, stackable and with grips for handling.

(Container)