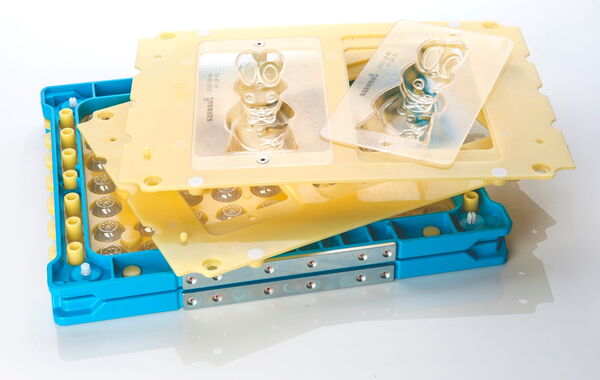

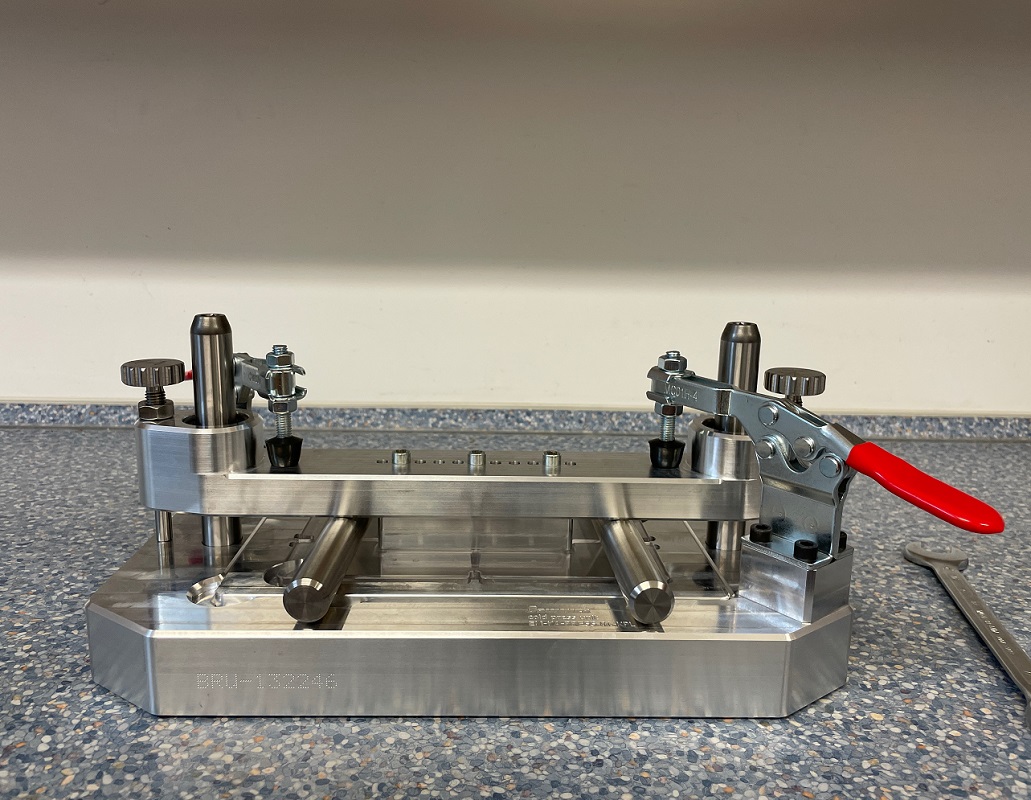

Sample cold stamping press

For manufacturers of filled chocolate products, it is important to know very precisely how many grammes of chocolate and filling are needed for any given article. It is therefore helpful for many products to be able to accurately determine the thickness of the shell.

Manufacturers who work with a cold stamping method can define the weight and the ratio of chocolate to filling right from the very beginning of the process when they first order their moulds. In the development of our products, we use these figures to determine the shell thickness to the nearest millimetre.

But what happens if it is not clear with which shell thickness a particular chocolate article should be produced? Or if the thickness of the filling and the chocolate cannot be precisely determined?

To deal with this challenge, Brunner has developed a new manually operated sample cold stamping press. It can be used before the production of the moulds to test what shell thickness/shell weight can be achieved with any given cold stamping press. At the same time, the effects the various shell thicknesses have on the production of the articles can also be trialled. This means that it’s possible during the early development stage of an article, for the customer to work both with us as the mould supplier and with their plant and equipment manufacturer to find the most appropriate design for the article in question. In addition, the new sample cold stamping press also enables customers to test out individual samples and to produce small batches of a product.

We show you exactly how to use the mould in our film.

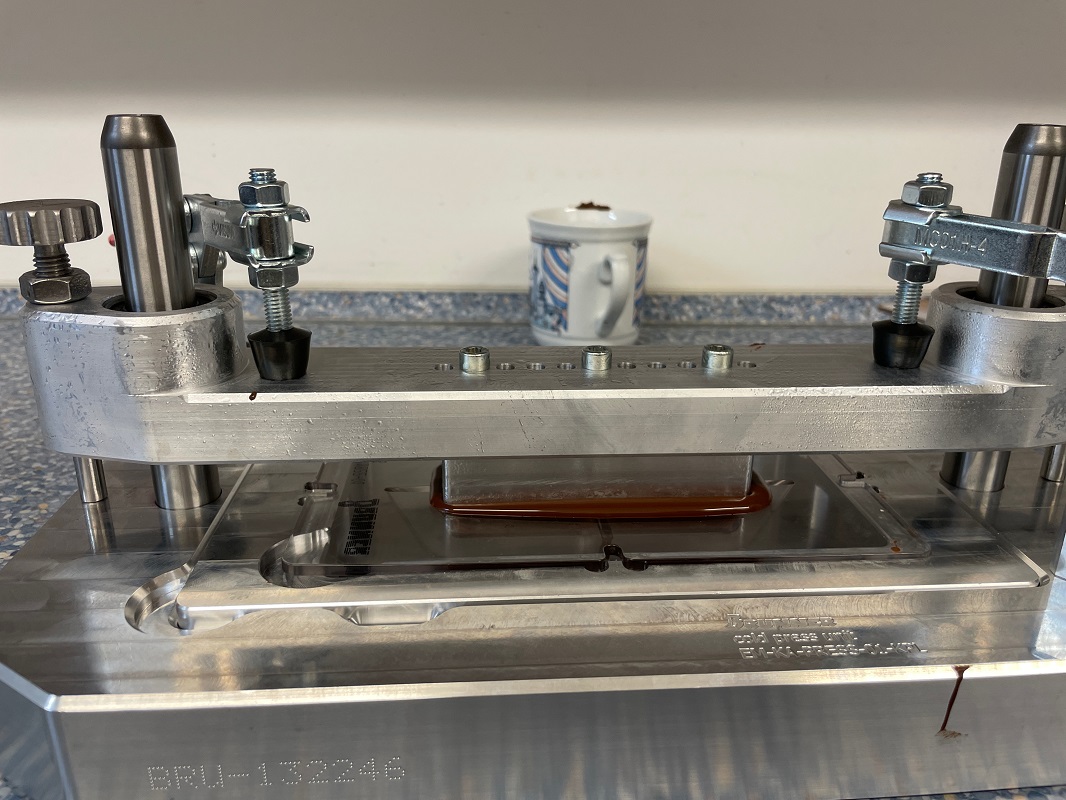

- Calibration:

- Insert individual sample mould

- Insert calibration bars

- Position the cold stamping unit

- Press down the tension levers using only moderate strength (use only the thumbs)

- Tighten the adjustment screw

- You should be able to move the calibration bars without too much difficulty

- Tighten the locking nut, making sure that the adjustment screw doesn't move

- Cooling the cold stamping unit:

- Put the cold stamping unit in a plastic bag and place it in the freezer

- Leave it for 90 mins at -18°C to -16°C

- The length of time will depend on the size of the article

- Testing shell formation:

- Fill the mould evenly, overfilling it by 10%

- Gently shake and tap it

- Insert the mould

- Position the frozen cold stamping unit

- Press down the tension levers

- Wait for between 10 secs and 1 min, depending on the size of the article and how cold the cold stamping unit is

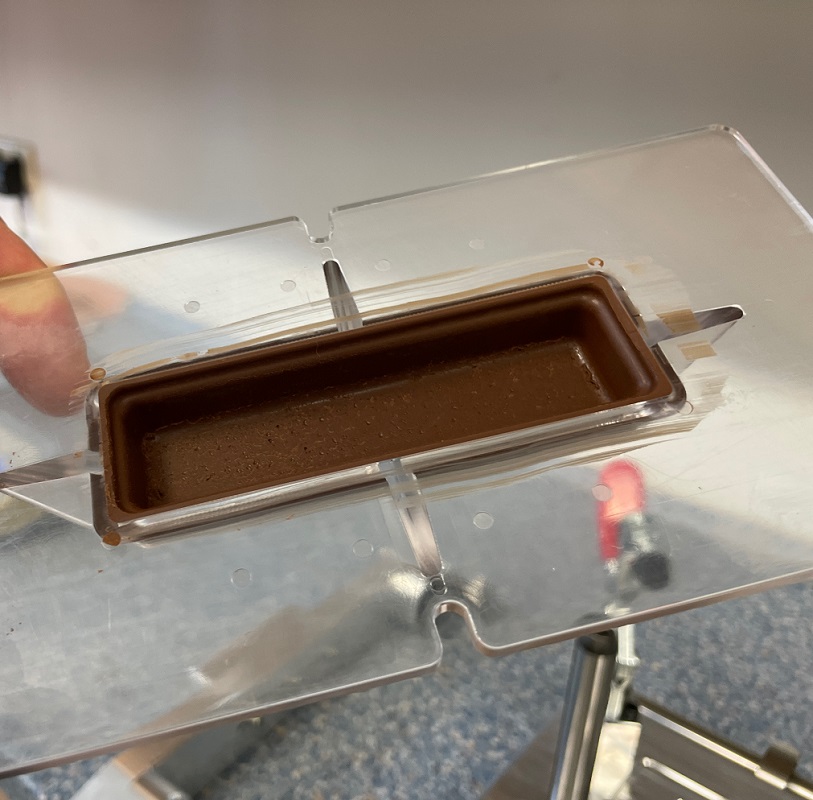

- Remove the cold stamping unit

- Remove the mould

- Scrape off any excess chocolate

- Cool at approx. 10°C

- The process can be repeated, providing the cold stamping unit is cold enough

If you have any questions on this process, please contact info@hansbrunner.de

Sample cold stamping press calibrating

Sample cold stamping press with chocolate

Cold stamping sample mould with chocolate