BRUNNER presents opportunities for producing very small runs

Every business owner who develops their own chocolate products knows the problem:

If you want to design your own chocolate items, you receive individual samples for testing, and then have to order a complete mould set, including tool costs.

Businesses with large production systems then have the problem that they can only test the sample manually.

And businesses with small-scale or manual production systems have the problem that the tool costs are too high, meaning it’s not economical for them to design their own products.

Hans Brunner GmbH has developed solutions for both cases:

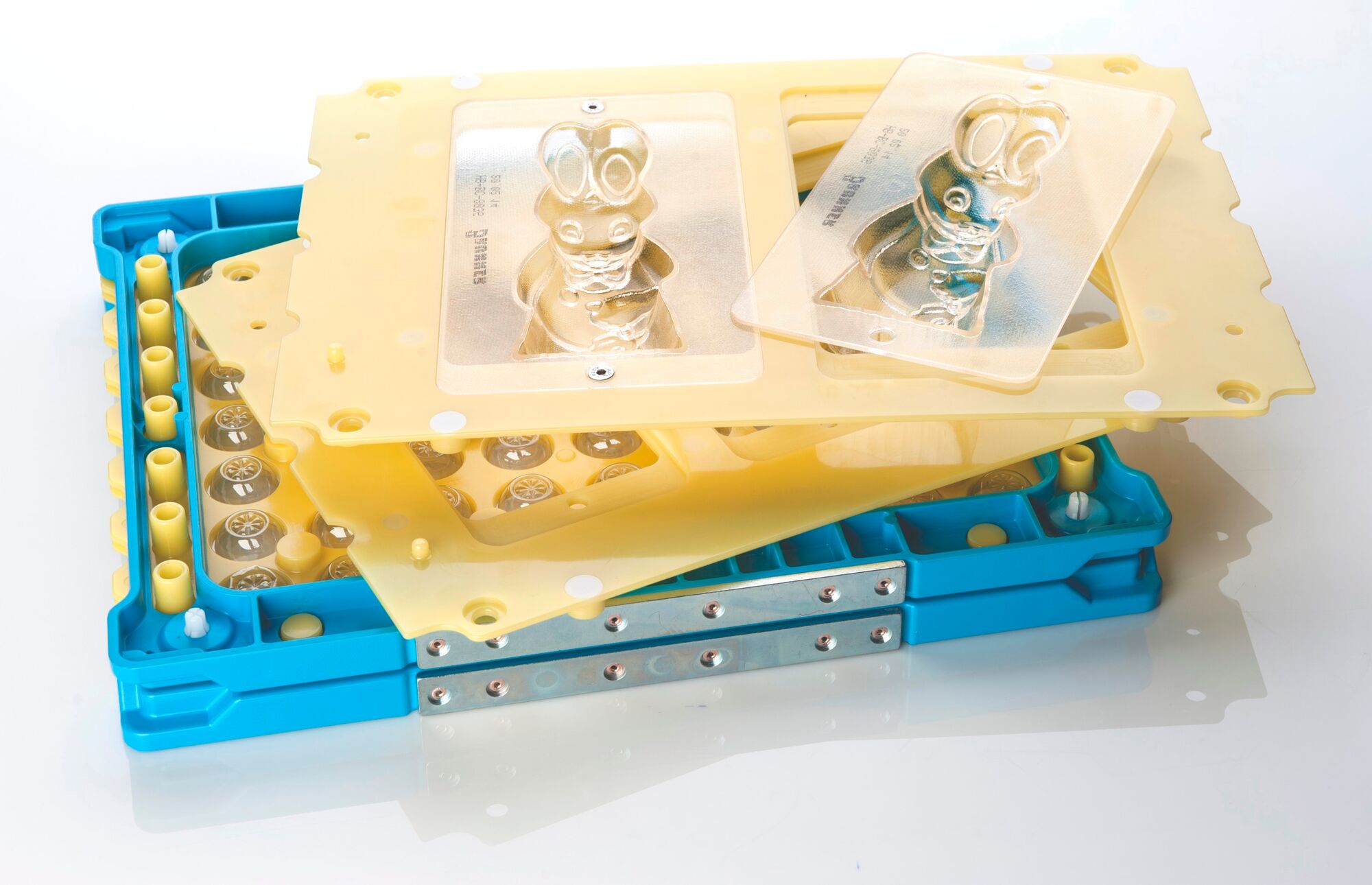

- Universal frame UR-0116 (size 275mm x 175mm)

- Blueflex Carrier UR-0109 (size 380mm x 295mm)

Both frames have standard sizes, meaning they are suitable for many production systems. In each case, individual samples are placed in the respective frame.

A manufacturer with large-scale production facilities can use it to run small test series (for example in the lab).

It now also becomes economical for smaller manufacturers to design their own products, because the universal frames are flexible in their use, with businesses only having to bear the low tool costs for one individual sample. The Blueflex Carrier can additionally also be used for multiple individual samples. And the Blueflex Carrier is also available with different recess sizes, meaning it can be used to manufacture both larger and smaller products.