Small-batch production of filled balls

Many companies making filled balls use semi-finished precursors, integrating pre-made balls into their production process. The effort of making balls manually and then filling them is simply too big.

Nevertheless, now and then, chocolatiers want to use their own chocolate to make balls, or apply the “bean to ball” process. In such cases, the chocolate producer has no choice but to carry out the laborious task of ball production.

To facilitate this process, BRUNNER offers several semi-automatic solutions, using which the filled balls can be produced faster and more simply.

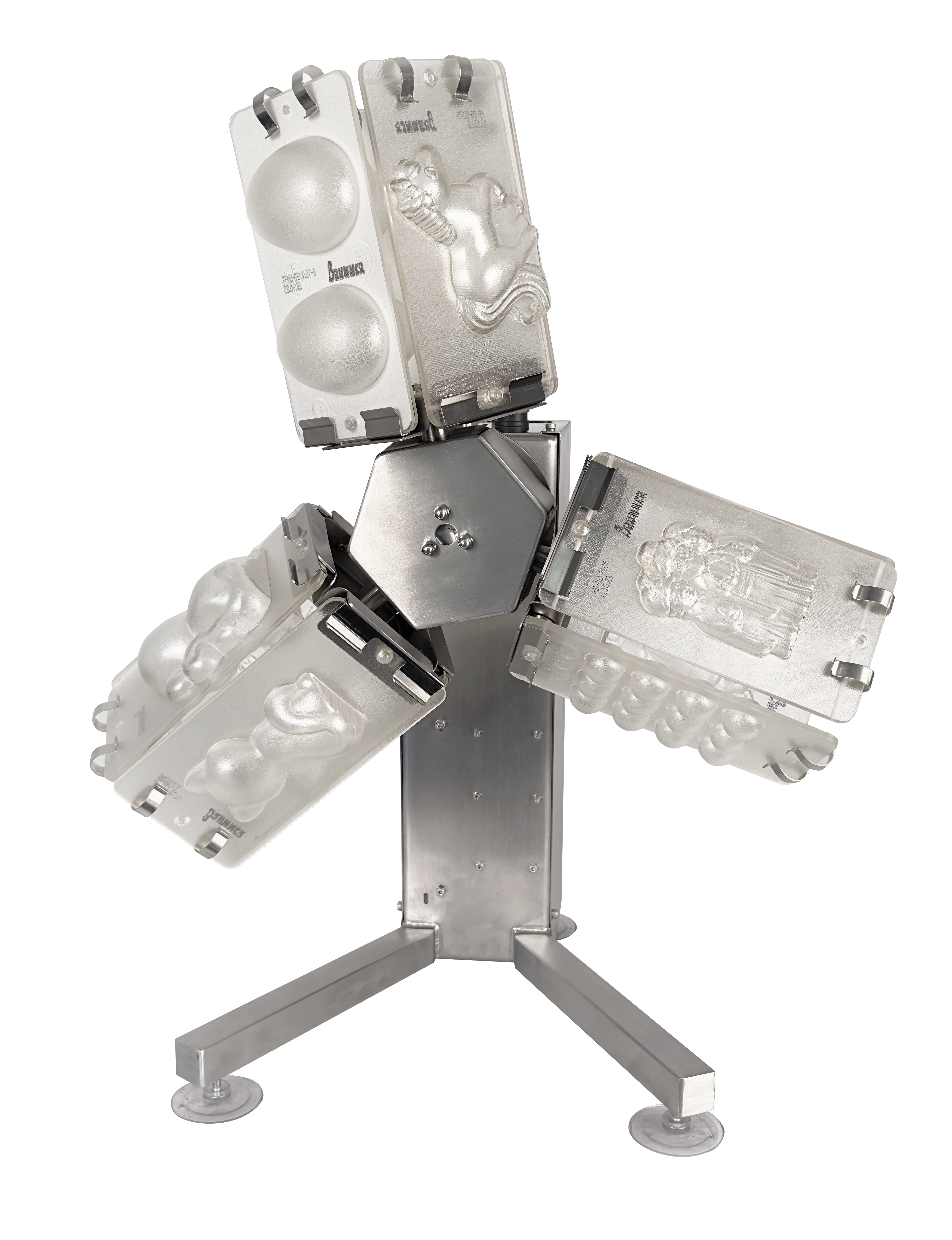

1. “Mini Spin” table spinning machine

The Mini Spin offers numerous advantages:

- low investment costs

- easy to use

- low spatial requirements

- clean work

- even shell thickness

- liquid fillings are also possible

- 12 moulds can be attached to the spinning machine at one time (i.e. 144 balls can be spun at the same time)

- The moulds for the Mini Spin can be used on a larger spinning machine with an adapter

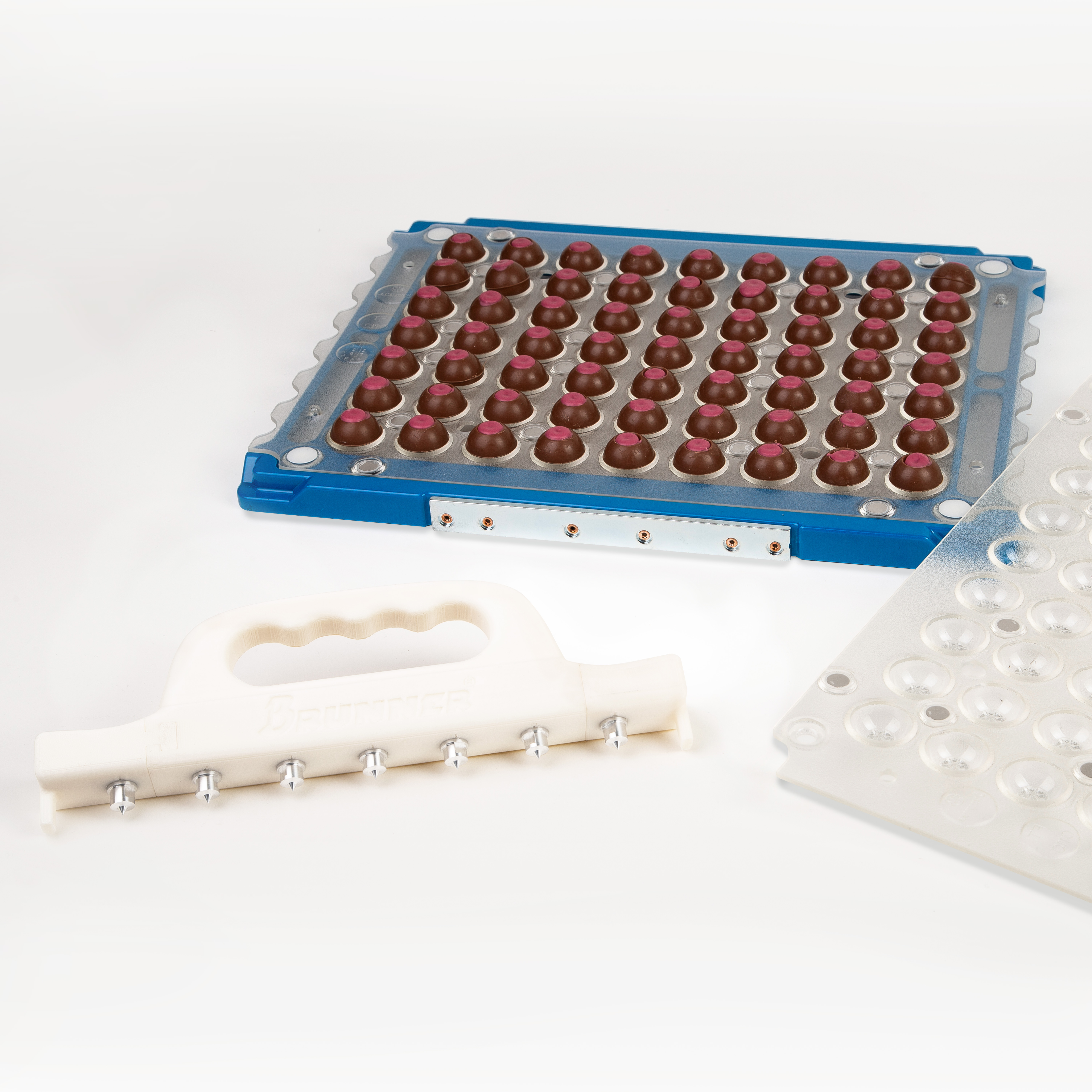

2. EASYTRUFFLER® System

With the EASYTRUFFLER® system and a hollow figure spinning machine, you can make your own truffle shells. The system combines the advantages of a solid chocolate mould and a single-use or multi-use blister pack. The solid upper part for balls or eggs provides perfect openings to insert fillings of a paste-like or liquid consistence.

It can also be used in all current one-shot dispensing systems in the 380 x 295 mm mould format. It can be combined in such a way that, with a solid polycarbonate upper part with filling holes, fully new opportunities present themselves. Thanks to this development, the uneven filling apertures, and the risk of plastic residues in blister moulds are a thing of the past. The lower part can be a single-use blister pack, multi-use blister pack or a solid polycarbonate mould.

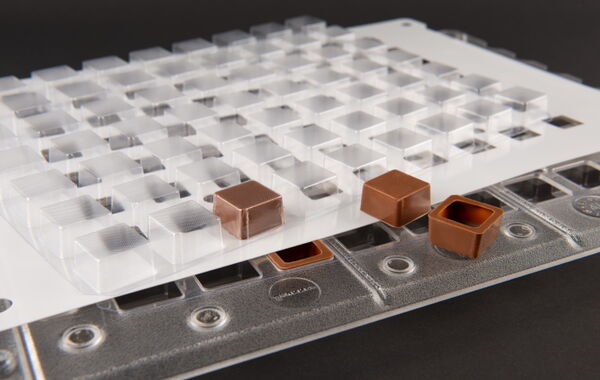

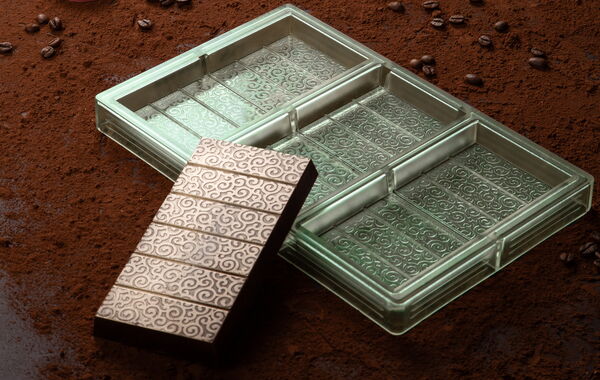

3. Compact one-shot systems for mould sizes 275x175mm

“One-shot” is a designation within the confectionery industry indicating a process in which the shell and filling of pralines and filled bars is inserted into the mould all in one go. Using an external tubular die, the chocolate for the shell is inserted into the mould. A little later, using a filling nozzle within the tubular die, the filling is dispensed into the mould. This takes place during the same work process with only a brief delay. To ensure a complete chocolate casing, the chocolate runs for a little longer than the filling.

To produce filled balls and eggs, double moulds are required. The upper half has an opening for the filler head.

BRUNNER’s double moulds are always being further developed and adapted to the existing demands.

They are suitable for all systems provided by every manufacturer of compact one-shot plants. Because of their thermopressed production process, BRUNNER moulds are very light and flexible, meaning the moulds need fewer magnets and are still extremely tightly sealed. The low number of magnets is better for the environment, your wallet and of course your fingers, as opening the moulds is much easier, requiring less force.

The height of the new moulds has been adjusted so that the lower part can be used both for balls and eggs.

Naturally, the moulds are made of polycarbonate and are as durable as ever