Sustainability

When it comes to sustainability, we here at Brunner have been taking a holistic approach for many years now. In other words, we simultaneously consider many different areas in which can make continuous improvements. So, for example, for more than 20 years, we have been sourcing our entire energy supply solely from hydropower and solar power. Ten years ago, we began producing our own electricity using photovoltaic systems. To date, these have generated more than 2,000,000 kWh of electricity, which we use to supply our injection moulding machines. We also use it to charge our personnel’s electric vehicles. This prevents line losses, as the electricity we generate is used directly on site. As well as providing electric vehicles, which meanwhile comprise more than half of our vehicle fleet, we also make bicycles and e-bikes available to our employees.

In addition, to make a contribution to minimising CO2 emissions, Brunner collects waste heat from the production of our chocolate moulds and feeds it into a district heating network. Apart from waste heat, the district heating network runs solely on renewable raw materials, sustainably heating more than 200 residential buildings.

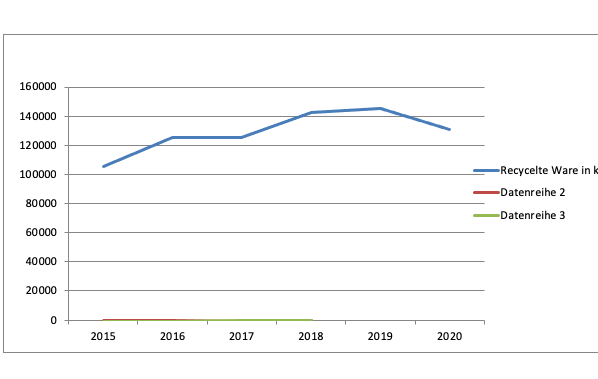

We also actively support our customers when it comes to recycling their moulds. We pledge to accept all returned chocolate moulds and reuse them appropriately. A research project is currently underway in our company, looking into how recycled plastic can be reused. In addition to this project, which is extremely important to us, in future we will also be replacing cars with combustion engines with electric vehicles, plus planting at least 30 trees on our site within the next year.

This all goes to ensure that, as well as helping produce the perfect piece of chocolate, your Brunner moulds are also sustainable, doing their bit for the environment.