The starting signal for recycling chocolate moulds

For Hans Brunner GmbH, sustainability has long been a matter of the utmost importance.

But also in the future, our stated aim is to be able to reuse material, and therefore conserve resources and protect the environment.

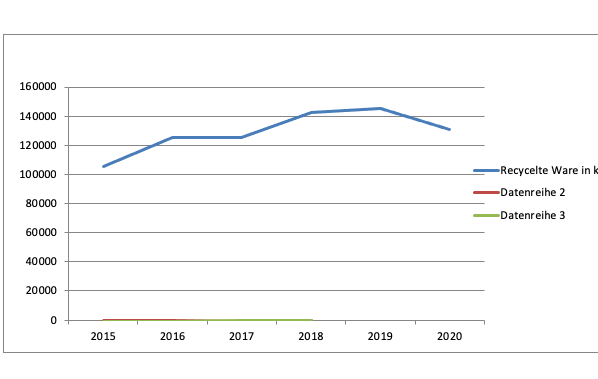

Since the middle of 2020 we have been the researching possibilities as to how to implement recycling loops for chocolate moulds. As part of this, we differentiate between materials that accrue as waste or remnants during production and material in moulds that our customers have already used.

We now have our own plastic mill, so we can crush leftover material arising during production to granulate, in order to test whether new chocolate moulds can be made from it. Series of tests are currently running, in which we are testing the recycled plastic’s material properties. Because we have the very highest quality demands, it is extremely important to us that even moulds made from recycled material fulfil our specifications and meet our customers’ high requirements.

Our long-term aim is to be able to produce moulds from material from recycled, used moulds – mould to mould (m2m).

Therefore, from January 2022, and in cooperation with external partners, we are starting a two-year research project. The aim of this project is to establish a recycling procedure that receives EU certification, so that moulds certified for use for contact with foodstuffs can be produced from used chocolate moulds.

This project comprehensively covers the topic of recycling in all its facets. All aspects will be examined and documented, spanning recyclable mould design, decontamination, separation, crushing and rheological analysis of the recyclate won in the process.

Customers who want to use moulds made from recycled plastic therefore receive a completely transparent overview of the entire process and material properties. They are therefore able to decide whether to use recycled materials for their new moulds.

Recycling conserves resources. As a result of the multi-cyclic materials cycle, less waste is produced, fewer resources are used and, compared with newly manufactured plastic, the CO2 used for producing the material is reduced by around 20%.

In this way, over the long term, chocolate moulds can be produced more economically and in a way which better conserves resources, which is good for customers and the environment alike.

If you have any questions or suggestions, or would like to work with us, our recycling experts are always available to assist you at recycling@hansbrunner.de.