Recycling Chocolate Moulds – Recycling Schokoladenformen

For Hans Brunner GmbH, sustainable business is an essential part of the corporate philosophy. Specially trained personnel, training sessions, long-term investment and energy efficiency in production are areas we have taken into account in our decision-making for a long time now. For decades, production remnants which accrue, such as for example metals, plastics or paper, have been separated on site and sent for recycling as part of the materials cycle.

Thanks to their long service life, our high quality moulds also play a part in conserving resources. However, we have gone one step further, and offer solutions for reusing our moulds:

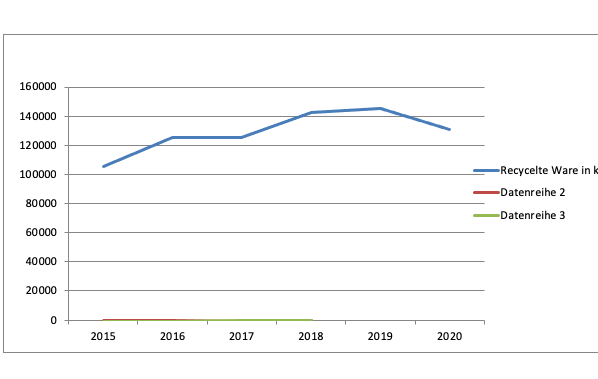

The used polycarbonate moulds are separated by colour and then supplied to the recyclable materials market. The sorted material is then sold to a manufacturer that can directly use polycarbonate as a raw material for its own products.

This saves natural resources, which would otherwise have been used to produce new polycarbonate.

There is also a solution for chocolate moulds containing metal components: Previously, at some expense, these had to be disposed of as waste metal. In early 2012, we entered into a partnership with the Steinhöringer Werkstätten (Steinhöring Workshops), a social organisation offering work to people with mental

or psychological disabilities, which professionally dismantles the moulds. Plastic, metal components and magnets are carefully separated, so they can be reused.

After the appropriate processing, metal components such as the elbow in Brunner centrifuge moulds (SE moulds) can be directly reused or supplied to the recycling market as scrap iron.

Neodymium magnets can be directly reused. As permanent magnets, they retain their magnetic properties, unless they have been exposed to high temperatures. The carefully removed magnets therefore undergo a strictly regulated sorting and inspection process before they are used in chocolate moulds again. Many years ago, Brunner developed a process in which the magnets are completely covered by plastic. This ensures the magnets do not come into direct contact with the chocolate, without negatively affecting their magnetic force.

Only new polycarbonate is used for manufacturing Brunner’s moulds.

Should you have any further questions, or require a quotation, our specialist Peter Mayroth would be pleased to assist. (Email mayroth@hansbrunner.de; Tel.: +49 (0)8093-9086-210).