Consistency & Progress

In 1935 Hans Brunner and Thomas Hauner registered a business in Munich for the production of confectionery supplies. Due to limited space, our founders had to look for a suitable production site soon and found it in Glonn, just outside Munich, where we still produce. Our success story began in an unused barn, which was renovated with untiring diligence by our Brunner employees at that time. Even at that time, know-how, teamwork, commitment and reliability were our strengths.

The young Rudi Schwaiger was given his uncle's company in 1980 and he is still our managing director and owner of the company Hans Brunner GmbH. Today, a total of more than 8500 square meters of space is available for the production of plastic parts.

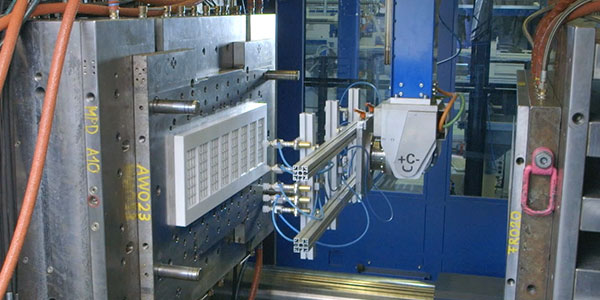

With 6 high-precision injection moulding machines and several thermopresses, we are able to control the production process optimally in order to produce sophisticated chocolate moulds of the highest quality. We are now about 120 specialists who develop, produce and internationally distribute the chocolate moulds at a single production site.

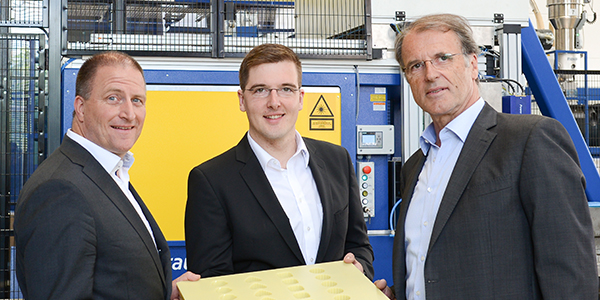

Since 2006 Markus Gebhart has been supporting us as second managing director.

Managing Director and owner Rudi Schwaiger will leave the management and ownership in 2024, to hand over the reins to his children. Christoph Schwaiger will become a Managing Director, working alongside Mr Gebhart. Stephanie Schwaiger will work independently as a controller and will report to the Managing Directors.

2024

Managing Director and owner Rudi Schwaiger will leave the management and ownership in 2024, to hand over the reins to his children. Christoph Schwaiger will become a Managing Director, working alongside Mr Gebhart. Stephanie Schwaiger will work independently as a controller and will report to the Managing Directors.

2023

- 90 % of the vehicle fleet are eco-friendly electric cars

- Changeover to environmentally friendly LED lighting

2017

- Rudi Schwaiger has been managing director for over 30 years and his children Stephanie and Christoph have been working successfully within the company.

- Electric cars added to the fleet

2015

80th anniversary of the Brunner company.

A new injection moulding machine is put into operation to ensure increased production efficiency.

2014

1st prize at the Energy Prize 2014 of the Ebersberg district for the optimization of the energy management of Hans Brunner GmbH

Extension by a new production hall

2013

TÜV certification ISO 50001

for Brunner's energy management system.

The TÜV certifications ISO 50001 and ISO 9001

are renewed at regular intervals.

2009

• Foundation of an in-house art studio

• Opening of the new onlineshop for standard moulds www.brunnershop.com

• A further milling centre in the tool shop supports the production process to meet the growing demand

2008

• Commissioning of a new injection moulding machine, with which moulds with a length of more than 1,200 mm can also be produced

• TÜV certification ISO 9001 for the quality management system of Brunner

2001 – 2005

Extension of the company building:

New construction of a production hall and an administration building.

Investment in a new injection moulding machine and a milling centre in the tool shop.