Technical innovations

Combining process optimisation with new and improved production methods has contributed to making further optimisations to the moulds. The evaluation of the use of new technologies is always based on a range of factors, above all according to their positive effects on the safety, durability and user-friendliness of the moulds.

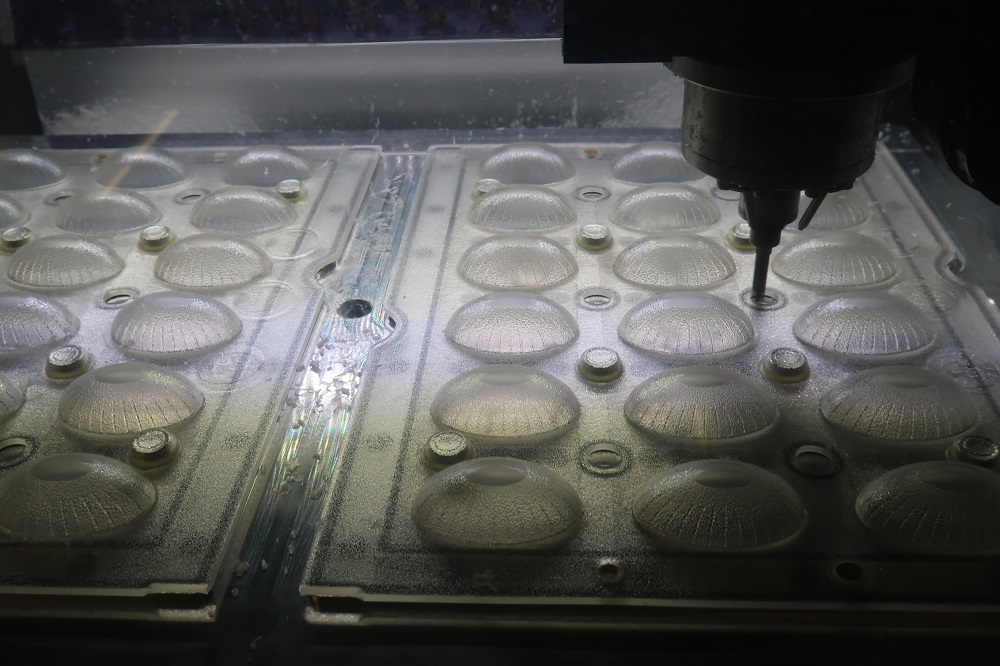

Milling plastic:

Thanks to the further development of our highly dynamic milling processes, moulds can be produced with smooth rear sides. This development prevents any possible dents or unevenness, which often lead to the development of cracks. Furthermore, a new processing method improves the quality and durability of the moulds. Our newly established process creates a smooth surface and rounded corners at the ribs and on the outside of the base of the mould. This allows the mould to run smoothly through the plant.

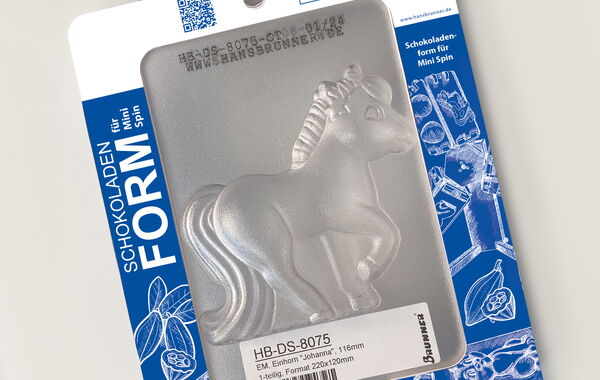

The recent expansion of our plastic milling capabilities allows us not only to use milling to improve our moulds, but also for new design opportunities.

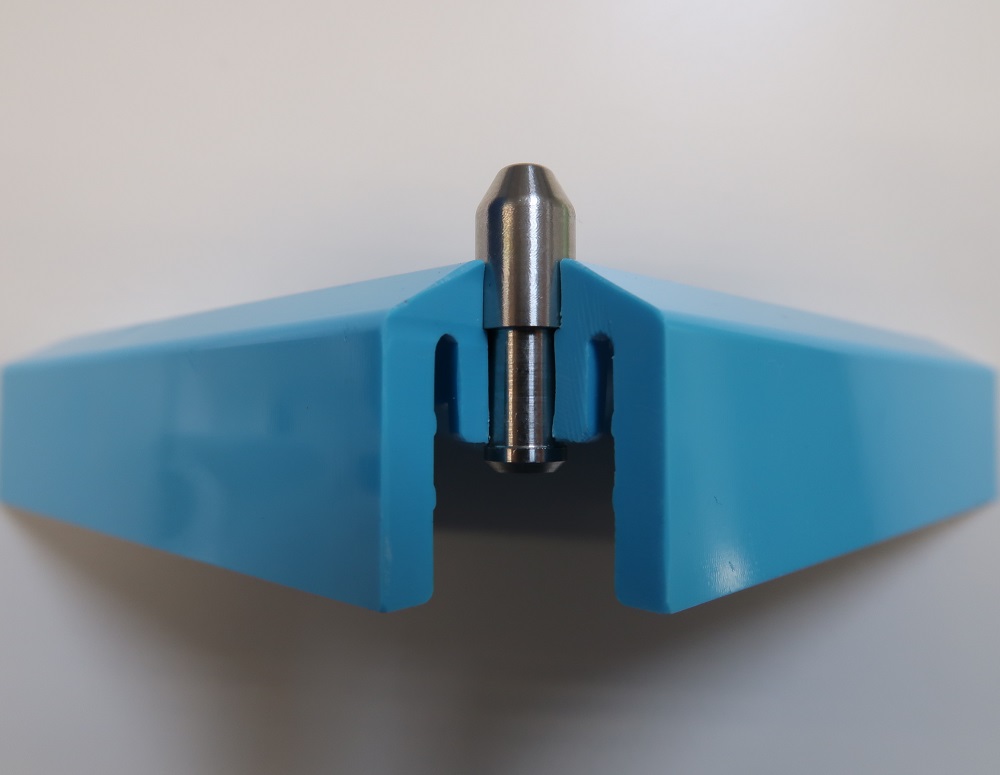

Metal pins:

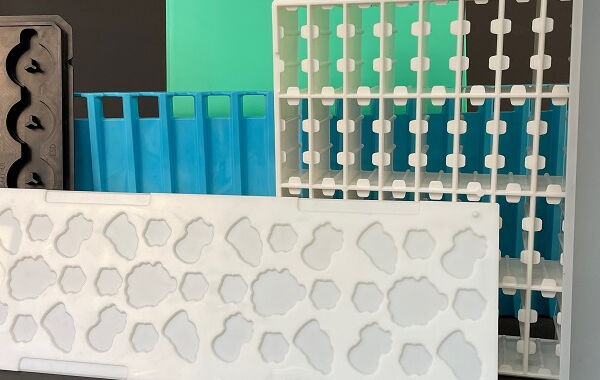

For our double moulds, we offer fixed and retractable metal pins. These provide unbeatable stability and findability.

Plastic screw connections:

We now offer hinges that can be screwed into plastic. This opens up whole new possibilities, e.g. for positioning and assembling de-moulded chocolates, which facilitates packaging.