A new area of application for BRUNNER moulds

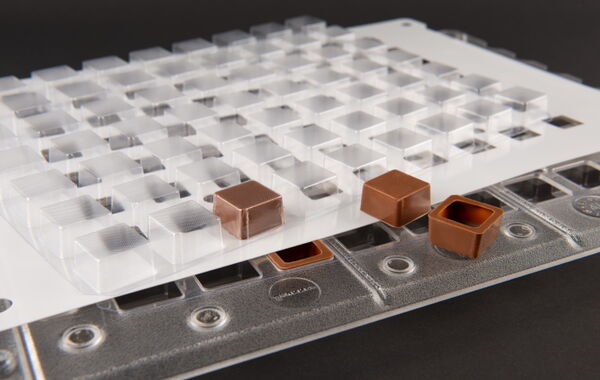

We have found a new area of application for our high-quality polycarbonate moulds: the production of fruit gums and jellies in plants that use the powderless process!

There are several benefits to the production of jellies with our moulds when compared to traditional production methods:

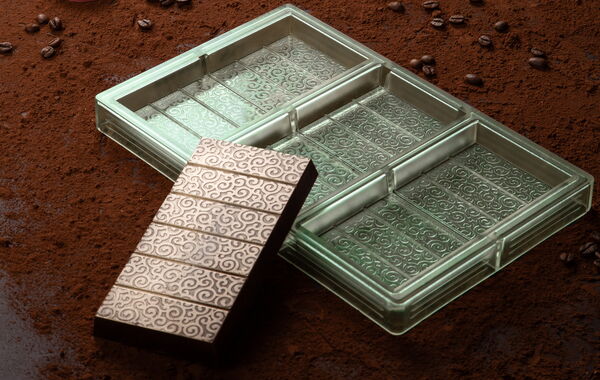

- A wide range of design options

Compared to traditional production methods, a much greater accuracy of illustration can be seen with our moulds. This opens up the creative possibilities for items, designs can have much more detail, which makes the jellies very appealing.

The moulds also allow the option of producing 3D items. This means customers will be impressed by the extremely detailed and beautiful designs of the jellies, e.g. in strawberry or lemon shapes.

- Hygiene

Because the moulds can be washed after every use, the risk of products being contaminated by foreign substances is minimised. In this way, even the highest standards for cleanliness can be met. The rigid shape makes it difficult for the jelly mass to escape, so that mass dispersion can be reduced.

- Seamless de-moulding

The individual items can be de-moulded as planned thanks to the mould's firm structure, meaning it's already possible to allocate the jellies correctly and precisely to their packaging in the plant.