Desk spinning machine

For artisanal chocolatiers and laboratories there are two possibilities to produce hollow figurines.

For the first you can use moulds with an open bottom, which require a complete manual processing. This method needs the lowest investing, but it is very time consuming (manuall production of an hollow figurine).

For the second you can use a spinning machine, which needs self-supporting spinning moulds. This method is linked to less working time, but it requires high investement cost, approx. 8.000 – 10.000 EUR (production of a hollow figurine with spinning machine).

With our new "Mini Spin" desk spinning machine, the investment threshold is significantly lowered and to the same time the manual effort is reduced. So the confectioner has more time for the work with chocolate, filling and designing.

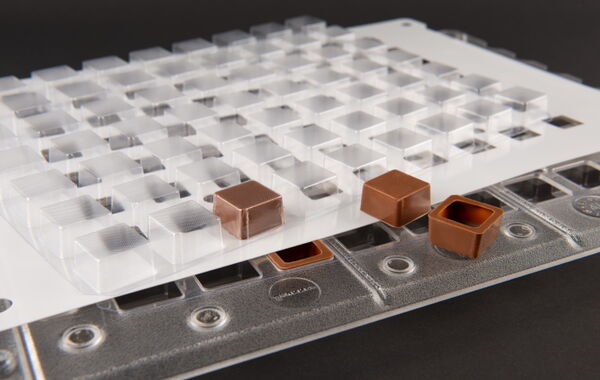

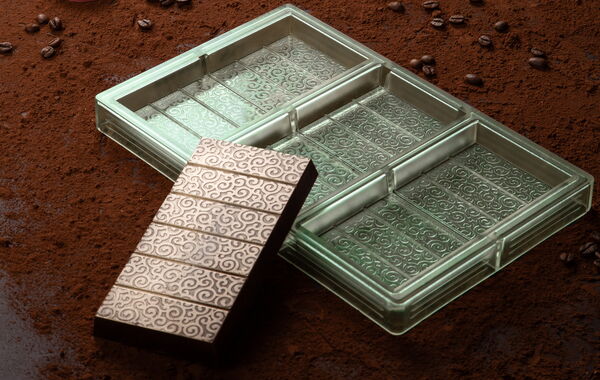

The cost for this desk spinner are approx. one third of the cost for a spinning machine, The needed moulds are usually single cavities, which are filled manually and are closed with clips. Finally they are fixed on the desk spinner and automatically spinned. So the time consuming process to produce the bottom manually is omitted.

12 single cavities can be fixed at the same time to the spinner. The size of the articles is limited to 174 x 100mm. The single cavities can be used in combination with our BLUEFLEX® Carrier also on a spinning machine.

Further information you can find in our online shop or you can contact our customer service at info@hansbrunner.de